Kwik Sand

High Early/ Rapid Stiffing Flowable Fill – City of Denver

On 6/20/18 VRM batched 12.5 cubic yards of HEFF088 for the demo pour for the City of Denver. Each load was initially tested for physical and hardened properties to verify targets were achieved.

Truck one was batched with 6.25 cubic yards and achieved an 8 in slump, 10% air content, with 122 lbs. per cu/ft and 78F.

The truck was sent to the pour location and was discharged into the trench. No signs of segregation were present at time of placement. Truck was left in one spot to allow us to verify flowability or how the concrete would move in the trench. The mix rheology performed well during the placement and flowed well, consolidated and penetrated fishers found in the soils in trench.

The second truck was batched with 6.25 cubic yards and was tested for physical and hardened properties. Initial slump of 8 in was recorded, 11% air content, 121 lbs. cu/ft, and 78F.

Truck was sent to pour location and began to pour out. This time we moved the truck and the truck chute during the pour. This allowed us to evaluate the difference in pour techniques and impact to early stiffening properties.

Two trenches were dug 24’X2’X3” to simulate field applications.

Each trench was filled to grade to allow for a 6 in paving cap could be applied for further evaluations.

The high early flow fill was tracked for early stiffing properties once in place.

Initially we had discussed the signs of no heel pressure in the surface of the flowable fill would be an indicator for the contractor to open to pave.

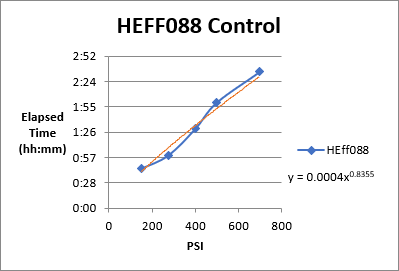

A hand penetrometer was also used to track the onset of acceleration in psi of resistivity per ASTM.

An initial target of 500-700psi in resistivity was utilized to allow for paving or capping the flowable fill in place.

The trench placement was periodically tested for penetration resistivity through the hand penetrometer, and individuals walking across the freshly placed flowable fill. In the first trench were the truck did not move we found an area that had a delayed set from the rest of the area. The area in question was the point of discharge of truck #1. Slight sings of bleed water were present in this area, mix water seemed to be concentrated in the localized area. The 2nd trench where the truck moved and poured out evenly no signs of delayed set were found across the surface of the placement.

Due to time frame we decided to postpone the High Early removable cap design which achieves 1500-3000psi in 4 hours. The next day at 18 hours old we backed a fully loaded 10-yard ready mix truck across the trenches filled with the HEFF088.

No signs of cracking, pumping, or sinking were found during this demonstration. Once this was verified we decided to batch and test the HEN1500 high early cap design to investigate early strength properties of the new capping design, bond ability to existing flowable fill, and removability.

Half of the trench would be capped with the high early concrete design and the other half would be paved with asphalt from CASI to represent real world applications commonly found in the local market.

On 6/21/18 four cubic yards of HEN1500 was batched and tested to demonstrate the early strength performance of the wear cap design.

The current design achieves 1500psi in 4 hours from placement and 3000psi in 6 hours with a 5-8-inch slump and air content of 1-5% respectively.

Concrete was placed by the VRM yard crew to ensure mix was workable and check finish ability.

(Videos available if necessary).

Rapid stiffing was reported at 1 hour from placement the cap achieved initial set and held weight of employees without leaving imprints in the surface of the slab. 2 hours from placement VRM pulled a fully loaded 10-yard ready mix truck across the capped design. Results show no signs of fracture or cracking at the surface.

Video available if necessary.

Once concrete cap and asphalt paving was placed, compacted, and tested. We then opened the section to traffic to evaluate the in-place trench fill. 300 passes with tractor trailers and 250 passes with ready mix trucks were documented over the time frame.

Once the 28 days of traffic conditions were completed cores were extracted by a third-party testing firm to examine by the VRM and City of Denver team.

(Video available by request).

The trench fill and cap design will stay in place to evaluate the durability to freeze thaw and look for frost heave through the 2018/2019 winter season. Initial bench mark will be completed by a survey team. In January and March, we will have the survey team back out to look at any changes in elevations of the in-place system.

In the spring the team will reevaluate the in-place system to verify no issues were found due to durability factors.

Results showed the concrete cap did bond well to the HEFF088 flow fill with no signs of fractures or collapse of the system below the capping design.

The asphalt paving did not bond well to the existing flow fill application. Note we did not know about tacking material. Next time we will look at applying tacking agent to the surface of flow fill before placing the asphalt material to ensure proper bonding is achieved.

Cores were then sent in for ASTM D560 freeze thaw testing of compacted cement soils to evaluate durability of the mix design.

Finally, we looked at the removability factor of the HEFF088 trench fill after curing for 30 days.

The use of a John Deere 310j backhoe was used of this section of evaluations. The north west corner of the demo section was targeted for removal.

Once asphalt cap was removed the HEFF088 was exposed without disturbing the flow fill. The back hoe made easy work of removing the flow fill, as seen in the attached picture the flow fill can be taken out with out issue. The material comes out in sliver like chunks initially, but once we got into the trench fill it would pulverize into a fine material.

Once we verified removability by back hoe we looked at the removability factor with a hand shovel. The HEFF088 was difficult to remove with a hand shovel but could be chipped away. The initial target of max 300psi was modified at this point to lower the max strength to 150psi.

HEFF150 was introduced as an alternative to the HEFF088 high early stiffing flowable fill mix design.

This would yield a max of 150psi in 28 days vs the previous design that would yield max 300psi at 28 days.

The mix would lower the Portland Cement content from 100lbs to 50 lbs. per yard to help lower the ultimate strength performance.

The stamped laboratory design was submitted to the City of Denver for approval.

Another 24x2x3 ft trench was made to evaluate the product in the field and verify performance was still achievable with the lower cement contents.

A 3-yard load of HEFF150 was batched and tested for physical and hardened properties.

The Mix yielded an 8 in slump, 12%, 117.2lbs/cu/ft and 78F and casted cylinders for 1, 2, 3, 7, 14, 28, 56, -day compressive strength.

The truck was then sent to the pour location and discharged into the trench.

Field results indicated the HEFF150 still achieved early stiffing properties in the 1-2-hour frame from placement.

No heel pressure could be measured at the 2 hours from placement, and still achieved the target 500-700psi in penetration resistivity at 4 hours from placement.

A Ford F-150 pickup truck was pulled across the filled trench at 4 hours from placement and showed no signs of tire imprints.

The HEFF150 high early stiffing flowable fill design was evaluated for removability.

The modified version was found to be easier for removability vs. the HEFF088 with the use of a hand shovel at 28 days old.

The decision to lower the ultimate strength from 300psi to max 150psi made a significant difference in hardened properties at 28 days. This should allow for contractors to work around existing underground utilities to remove the trench fill product if necessary.

As seen in the pictures below the Kwik Sand technology could be removed with a back hoe and a hand shovel.

The material initially breaks off into sliver like pieces, once you’re into the flowable fill it begins to pulverize into a fine material.

The Conclusion

In conclusion the VRM team feels the Kwik Sand product offering is a viable solution to fast track construction practices. The product can be utilized in time sensitive projects to allow the customer to backfill or pave in hours instead of days or weeks like typical flowable fill product offerings. The product can be removed with a back hoe or hand shovel when necessary. The rapid stiffing flowable fill holds up to moderate to heavy traffic conditions without showing signs of failure before or after 28 days.

An unrealized benefit was found in drying shrinkage with this technology. Unlike typical flowable fill products that tend to have a higher shrinkage values our design show’s little to no shrinkage in comparison. This will help ensure pavements placed on top of the system will have a lower chance for causing unwanted formations in the pavement surfaces in the future. This will also aid in the insurance that the bond between the virgin material in the trench or fishers and the Kwik Sand. This should mitigate the migration of foreign materials to enter the system and impact the durability factors of flowable fill material below the grade. Attached below is the stamped mix design for the City of Denver.

The HEFF150 shall be used for flowable fill applications. At no time is the HEFF150 to be used as a temporary cap or wearing surface for traffic conditions. The HEFF150 can be placed and should be capped with concrete or asphalt 2-4 hours from placement. At this time traffic can be opened to the pour location. When ordering this product make sure you have enough time in the schedule to account for the recommended time frame set by VRM.

When placing the HEFF150 the time will start once you have filled the last hole on the project. Regardless of how long it takes to empty the truck you will need to stick to the start time based off the last trench or hole filled. Be careful of areas that will be placed in a turning radius. Again, this is not a removable capping design so please do not attempt to place in these areas. If you are planning on paving or capping over the HEFF150 rapid stiffing flowable fill, then the turning radius will hold up to traffic.

The HEN1500 can be a viable solution for a design that could be used as a wearing surface and can be placed on top of the HEFF150 flowable fill.

The HEN1500 mix achieves 1500psi in 4 hours and 3000psi in 6 hours from placement. This allows you to return to the pour location to remove the cap design and place the approved design for that application.

(Removable/Temporary Wear Concrete Cap) If a customer would like the cap to achieve 1500psi faster than 4 hours VRM would be willing to investigate the ability to manufacture the modified version of the High Early Removable cap design if requested.

Standard specifications for this design for physical properties are 4-8” slump, 1-5% air content. Concrete should be placed and finished like typical class E high early concrete practices. Ambient and concrete temperatures and travel time will impact your workability window of this product offering. Through admixture formulations VRM can mitigate the environmental impacts to the hydration process.

This ensures the product performs consistently from day to day.

ECO Drum

With this technology comes some risk to the producer so we have implemented the risk reducing technology (Eco Drum).

Due to the violent hydration profile of this material we have a difficult time saving the concrete drum once this product takes off. Typical levers to control the concrete or left overs do not work well. Once the HEFF150 takes off we can stop the reaction. This can result in the product hardening in the revolutionary truck drum.

In my experience the contractor is required to have a washout area for our trucks, but with limited space onsite they might not have one for use. This would be catastrophic to our trucks if this was to happen. Therefore, we have decided to roll out the Eco Drum if our customers decide to utilize the Kwik Sand product lines.

How does it work?

Each driver will carry enough Eco Drum to control 10 yards of product. If there is an issue on the jobsite and the customer is unable to pour out the load, then the driver will add the risk reducer to the truck. The product will de hydrate the cementitious materials stalling the cement hydration process and not allow the product to reach the hardened state..

The customer will be required to purchase the Eco Drum based on per treaded yard. Each treated yard will cost ($xx.xx), and the driver will be able to return to the plant location to discharge leftover HEFF150 in the yard.

If the customer over orders the HEFF150 which is typical behavior. Again, there would not be enough time to get the load back to the plant location to discharge before it hardens in the revolutionary truck drum without the use of an eco-pan. Once the driver returns to yard he can discharge the leftover materials. The customer would be obligated to purchase the ECO Drum by per treated yard. Driver will let the customer know how many yards are left and how many bags of Eco Drum is required.

Best Practices

- In a perfect world a 24-hour notice is required to place an order for the HEFF150, or HEN1500.

- Customer must sign best practices before they can place an order. Certified finisher by VRM

- Understands the do’s and don’ts, exceptions and obligations. (What can it do and what can’t it do)

- Key question is answered do you have enough time to place this technology before you need to open.

- How far away is the project from the plant location?

- Dispatch must receive call from customer to release truck. Customer must be ready to unload truck when they arrive. Any delays can add risk to the truck resulting in the use of Eco Drum. We will not send out an order unless the customer calls to release!!!!! No exceptions.